What is CSST?

CSST stands for Corrugated Stainless Steel Tubing. It is a flexible, stainless steel pipe used to supply natural gas in residential, commercial, and industrial structures.

It was first developed in Japan in response to a need for flexible gas piping that would perform better than rigid piping during earthquakes. It was approved for use in the United States around 1991

CSST vs FAC

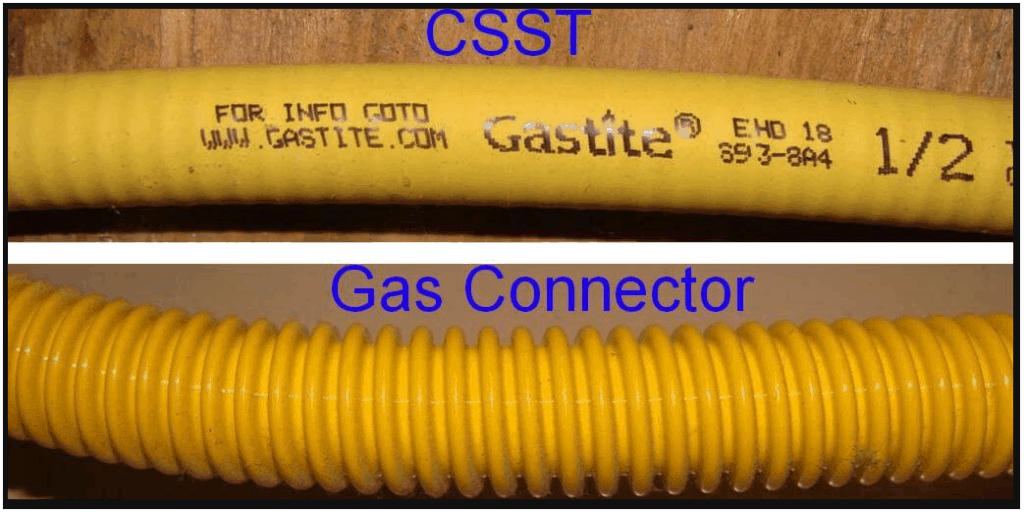

CSST should not be confused with a Flexible Appliance Connector (FAC) sometime referred to as corrugated stainless steel connectors (CSSC). Since they both have similar sounding names and can have a similar appearance in shape and color they are sometimes confused. Both are made from stainless steel and can be yellow in color. FAC are short lengths of piping between 1 to 6 feet in length with a factory installed connector at each end. CSST is usually larger in diameter (3/4”– 1”). FAC can be different colors (yellow, orange, black, gray) older FAC brass/copper color and are prone to leakage and should be reported for replacement. CSST is almost always yellow or black depending on the type. The other major difference is that FAC is painted and the corrugations are visible where CSST is sheathed and the corrugation is not visible.

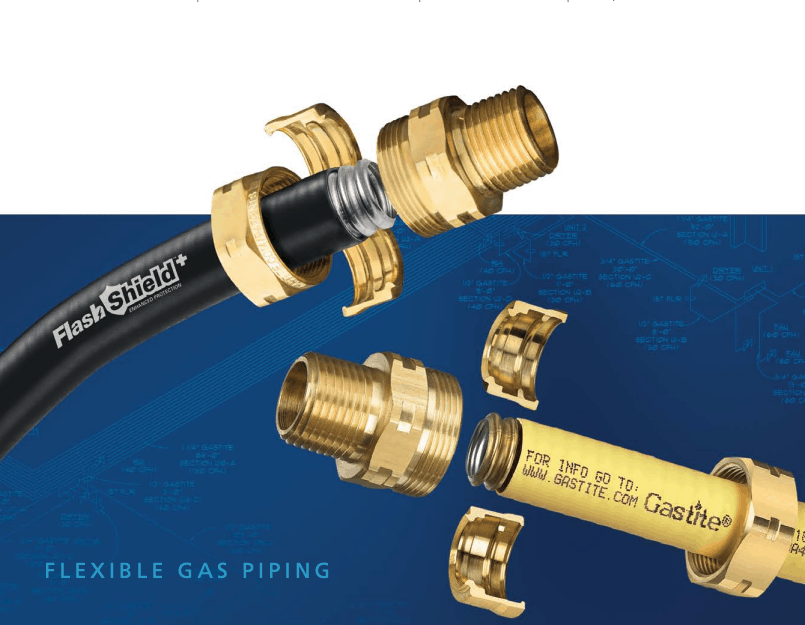

Types of CSST

There are two types of CSST those that are not ARC resistant which is yellow in color and CSST that is ARC resistant which is black in color. The yellow-colored CSST was the first type used and will be present in earlier installations. Arc resistant CSST with a black covering was first approved for use around 2012. Both types of tubing are shown at the top of the article.

Inspection Points

The following points provide general guidance and are in no way exhaustive. Like will all specialized, proprietary components and systems, the manufacturer’s installation guidelines, and local code take precedent.

- Installation Guidelines

- First and foremost manufacture’s installation guidelines take precedence over any other specifications, recommendations, or codes. So when in doubt always defer to the manufacturer’s instructions.

- To properly inspect CSST you’ll need a copy of ANSI LC-1/CSA6.26 and the Manufacturer’s Installation Guidelines

- Because of these requirements, most inspectors should disclaim CSST

- Proper Support

- A common and easily overlooked defect is proper support. Typically you will see ¾ inch or larger CSST and this requires support every 8 feet. The measurement for support is along the CSST piping not just in the horizontal plane. Pay attention to support at manifolds and fittings because leaks are more likely at these points. Generally, plastic supports are not recommended/allowed as the material can melt during a fire. All supports should be of sufficient width and strong enough to support the piping without sagging or crimping.

- Stationary Appliance

- Connection to and installation into appliances is allowed as long as the appliance is secured and is not moveable. Furnaces, gas packs and decorative fireplaces are acceptable but dryers, ranges and gas grills are not. CSST can be installed in a masonry fireplace but only for gas logs and not for a wood-burning gas log lighter. When installed in the firebox for gas logs the protective covering should be removed.

- Penetrations

- Check all penetrations especially those through cement or masonry walls. A watertight non-metallic sleeve should be present or the proper bulkhead connection. Contact with cement can cause corrosion.

- Is a sleeve or bushing necessary when entering/exiting a cabinet? Again this is dependent on the manufacture’s guidelines but it is generally acceptable to install CSST into a cabinet. There is however a requirement to avoid contact with sharp objects and metal edges. The best practice is to either install a bushing, sleeve or use hard piping. Alerting the client to the potential risk and suggesting improvements is the best-recommended approach.

- Damage

- Check the condition of the outer covering it should not be damaged. The most common damage is from installation. All damage to the tubing and covering must be reported. Make sure to check as much of the exposed piping as possible looking at all sides.

- Another common defect is damage caused by improper or over-tightening of the connections. This can cause the thin piping to deform and crimple increasing the risk for a leak. Pipe dope should not be used in conjunction with CSST fittings.

- Exposed Tubing

- Trimming back the protective covering and exposing the stainless steel tube is dependent upon the manufacturer’s recommendations but, generally, it is allowable for the yellow-covered piping but not for the black arc-resistant material. Whenever exposed tubing is seen make sure to check for corrosion. Any corrosion on the tubing and/or fittings should be noted and reported.

- Direct Contact & Puncture Protection

- CSST should not be in direct contact with any metal, or electrical wiring and must be protected from mechanical threats. When possible, check for nailing/striker plates in the same manner as you would for plumbing or electrical installations. This mostly will apply to pre-drywall inspections but it can apply to existing homes in those areas where the piping is visible such as garages and exterior applications.

- Exterior Application

- CSST is approved for exterior use but must be properly protected when mechanical damage is possible exposed tube is not allowed.

- Paint

- Painting of CSST is not allowed as the paint could corrode the metal.

- The manufacturer’s markings should be visible so that proper identification can be made.

- Bends

- The flexibility of CSST allows for ease of installation and fewer fittings. However, there are restrictions on the bending of CSST. This is another commonly overlooked defect. 3 inches is the minimum bend radius for ¾” and smaller CSST and 5 inches for 1-1 1/2 inch diameter piping.

Bonding

Bonding is the one CSST inspection point that is called out the most and also causes the most confusion and grief for all parties involved. Initially, bonding was not required by the code(s). Expect push back from the seller and their agent as most are well aware of when the bonding requirement was included in the code and they will claim it’s not required. However, as we mentioned the manufacture may have always had a bonding requirement but it was not followed or enforced.

We are allowed by our standards (NC) to call out safety concerns and alert our clients to the potential risk to both the property and individuals. In this case, the North Carolina Licensing Board has provided the following recommended language for CSST.

The gas piping system of this home includes corrugated stainless steel tubing (CSST). This flexible gas line system has specific installation requirements related to electrical bonding, designed to reduce the potential for lightning related electrical arcing that can perforate the tubing and result in gas leaks or fires. During the home inspection, the CSST could not be verified to be integrally bonded or to have a bonding attachment. An electrical contractor should be consulted for a complete evaluation of the CSST installation to ensure the presence of an electrical bonding path.

North Carolina Home Inspector Licensure Board

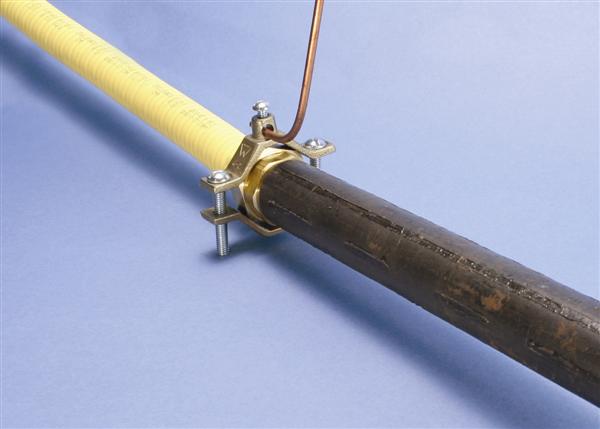

If bonding is present, some key points for the inspection are:

- The bond should be placed at the first fitting location where the CSST is connected to the main gas line. If steel piping is not present then the bond must be placed at the first CSST fitting. Bonds cannot be randomly placed or connected to the tubing.

- The bonding conductor should be no less than a #6 AWG copper wire (solid or braided). It should be connected to the grounding electrode at the service equipment. However, the use of an additional grounding electrode when it is not practical to connect at the electrical service is allowed. This will usually be seen on retrofits of older installations where the gas meter is on the opposite side of the home from the electrical equipment.

- Check the clamp. Clamps on brass fitting should be either brass or stainless steel, not galvanized steel. Galvanized fittings are allowed when connecting to black iron piping.

- For some newer arc resistant CSST products the manufacture may not require additional bonding beyond the normal bonding required of all metal gas pipes. Gastite Flash Shield brand CSST is one such manufacture. Still the building officials may require it.

Gallery of Defects